IMD _Institute of Media and Design

- 2024

- AD +10 Meter _Into The Open_01

- AD +10 Meter _Into The Open_02

- AD +10 Meter _Into The Open_03

- FT F60 bridge Brandenburg

- FT Cologne Deutz harbor

- AD Grossmarkthalle Cologne_01

- AD Grossmarkthalle Cologne_02

- AD Grossmarkthalle Cologne_03

- AD Grossmarkthalle Cologne_04

- AD Grossmarkthalle Cologne_05

- AD Marine Research Center Stavanger

- AD Fun Palace ICC Berlin

- FT Fun Palace ICC Berlin

- RO Architectural Narratives

- MD Tegel-Süd

- 2023

- 2022

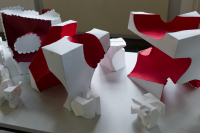

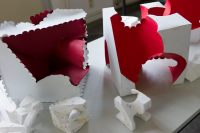

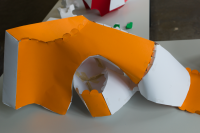

- EX | GREY BOX TESTING _Workshop

- EX | GREY BOX TESTING _ALMERIA

- EX | GREY BOX TESTING _KOLWEZI

- EX | GREY BOX TESTING _SILICON

- EX | GREY BOX TESTING _AUTONOM

- AD In Limbus

- AD Atlantikwall

- AD Zentrum für Fotografie_01

- AD Zentrum für Fotografie_02

- AD Zentrum für Fotografie_03

- AD Zentrum für Fotografie_04

- AD Immigrants hotspot Calais

- AD Spreepark Berlin

- AD Calais

- RO Cooling Clay

- MD Dover

- MD Power of Spaces

- MD Flickwerk

- MD Scaffolds

- 2021

- AD Gasometer Schoeneberg_01

- AD Gasometer Schoeneberg_02

- AD Gasometer Schoeneberg_03

- AD Gasometer Schoeneberg_04

- AD Perception as Reality

- AD Ebertplatz Koeln_01

- AD Ebertplatz Koeln_02

- AD Ebertplatz Koeln_03

- AD Rural Taxonomy - Rheinland

- VR Agora Virtuell

- MD Weaving Worlds

- MD Behind the Scenes

- MD Borders Crossing Borders

- MD Perspektivwechsel

- MD Ghosts of Beirut

- MD Flux-House

- MD Peripherie BS

- 2020

- EX NEUXKÖLLN

- CO VR Symposium, Hannover

- FT Schnöggersburg

- EX VR-Präsentation TU Berlin

- AD Assemble - DisAssemble_01

- AD Assemble - DisAssemble_02

- AD Assemble - DisAssemble_03

- AD Rural Taxonomy - Lausitz

- AD Virtual Reality Center

- AD Allotment Garden Berlin

- AD Cinematheque for Berlin

- AD Neft Dashlari

- VR Unbefugte Nutzung

- MD Rural Taxonomy - Almeria

- 2019

- EX Kino der Moderne

- AD Yellow Tower Hildesheim

- AD Silk Road Duisburg

- AD Ein ZKM für Berlin_01

- AD Ein ZKM für Berlin_02

- AD European Hub Inden

- AD ÖKOstrie 4.0_BioDigital

- AD Reverse Architecture Chemnitz

- VR Zeichnen virtueller Raumbilder

- VR Entwerfen in der Virtuellen Realität

- VR Being a Drone

- VR Raumzeichnen 1

- RO Intrinsic Acoustics

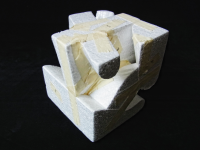

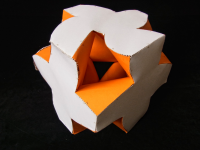

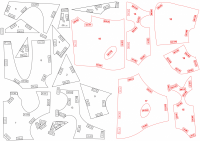

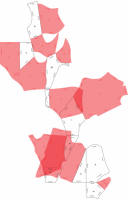

- MD Digital Stereotomy

- 2018

- EX Roboramics _FUTURIUM

- AD Avus North Curve Berlin

- AD Wuppertal Reloaded

- AD Neues Sehen

- AD Benno Ohnesorg

- RO Endless Space

- RO Roboramics

- AR Augmented Realities

- VR Fieldstation Berlin Teufelsberg_2

- VR Fieldstation Berlin Teufelsberg

- MD Bending Bamboo

- MD Skins

- MD flow fly fold

- MD From Idea to Design

- MD Digitale Fabrikation

- MD Spatial Informa(p)tions

- 2017

- CO With eyes wide shut

- EX Photo-Based Architecture

- AD In.Form the Void

- AD Transforming Tegel

- AD The space could also be different

- VR Mit weit geschlossenen Augen

- VR This is real

- VR Designing Virtual Realities

- LE Image-based Architecture

- RO Hello Robot

- MD Ghost towns

- MD Motion - Space - Object

- MD Dynamic Surfaces

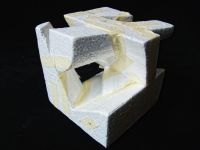

- MD Spatial modular systems

- MD Foams

- MD Tomorrow land

- 2016

- 2015

- EX Bigger than life

- AD Checkpoint Charlie theater

- AD Honecker Bunker Prenden

- FT Honecker Bunker Prenden

- RO The Unseen Ornament

- MD WovenWoodWall

- MD Bunkerarcheology

- MD Upside down

- MD Floating Concrete Shells

- MD One to One

- MD Foldable Surfaces

- MD Image Based Architecture

- MD Linear Constructions

- MD Reconstructing Tschernichow

- MD Cut Fold Turn

- MD Metabolism Printing

- MD Enter the Void

- 2014

- EX Smart modular systems

- AD Nuremberg transscription

- AD Avus north curve

- AD Time out zones

- FT Time out zones1

- FT Time out zones2

- AD Hacking Berlin Teufelsberg

- FT Hacking Berlin Teufelsberg

- AD Moma Tower

- AD Highrise Topology

- MD The Continuity of Space

- MD Continuum Structures

- MD Dissolving Funnel

- MD Photopology 1

- MD Cut to fit

- MD Parametric tiling

- 2013

- 2012

- 2011

- 2010

- EX Explosee

- EX Tape Deck

- AD Sustainable Center Afsluitdijk

- AD Hangar J 1000

- FT Junkers+Bauhaus Dessau

- MI Hangar J 1000

- MD Medial design processes

- MD Responsive_wall

- MD The flow of things

- MD PhotoStitching Reality

- MD Space projections

- MD Urban_bit_map

- MD Google's street view

- MD Structural constellations

- MD Intersection space

- MD Parts of space

- MD The section maker

- 2009

- 2008

- 2007

- 2006

- 2005

copyright _IMD